What is risk in procurement?

Risk in procurement is the impact of uncertainty on value for money.

Risk is a factor in value for money. Risk events may impact any of the other financial and non-financial factors in value for money: fitness for purpose, supplier capability, broader government objectives, total cost of ownership, and timeliness.

Risk events may have negative or positive (opportunity) impacts. They may occur within or external to an Agency, and at any time in the procurement lifecycle, including after a contract ends.

How is risk managed in Victorian Government?

There are risk management frameworks and processes at whole-of-government and Agency levels for managing risk generally, and procurement specifically.

Whole of government

The whole-of-government level includes:

Agency risk management framework

At an Agency level, risk management may include:

- risk management governance, processes, and audit

- procurement governance, strategy, policies, and processes

- category management (if applicable)

- risk management in individual procurements during planning, market approach, and in contract

Use your agency's procurement policies and processes for procurements.

Risk may be managed at category level. Check whether your procurement can benefit from this head-start on risk planning.

In some procurements, Agencies may seek support from their broader risk management framework or the whole-of-government framework.

Who is accountable and responsible for managing risks?

The financial delegate is accountable for demonstrating value for money, which includes risk.

Decision makers, managers, and team members may have formal responsibilities according to the Agency’s policies and the governance structure for a procurement. The sourcing and contract managers typically hold primary responsibility for managing risk in their respective stages of a procurement.

Responsibilities should be allocated for:

- maintaining a risk register

- implementing each risk treatment

A dedicated risk manager may be appointed for high complexity procurements.

Informally, anyone may identify risks and propose treatments.

What is the process for managing risk in a procurement?

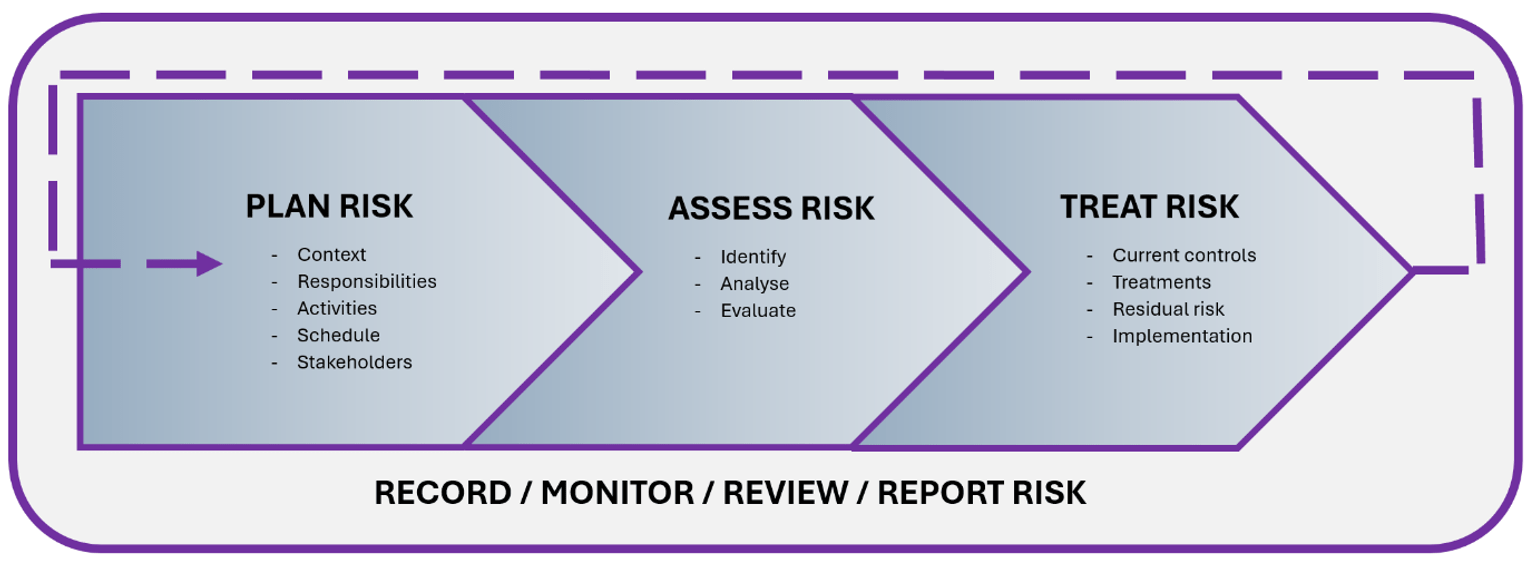

The risk management process for a procurement involves: Plan; Assess; Treat; and Record, Monitor, Review and Report.

The process of Plan, Assess, and Treat risk may be repeated at key stages in the procurement lifecycle; for example:

- market analysis and review

- offer evaluation and selection (prior to signing a contract)

- annual contract reviews, variation processes, and exercising options to extend

The process may also be repeated when the risk profile of a procurement changes significantly. For example, a natural disaster, war, or pandemic may disrupt supply chains and change the risk profile.

Plan risk

Plan to manage risk. Do this when developing the project plan for a procurement.

Risk may arise early in the procurement process – be prepared.

Scale risk planning according to the complexity of the procurement.

A plan may include:

- context

- responsibilities

- activities

- schedule

- stakeholders

Assess risk

Assessing risk involves three steps: identify, analyse, and evaluate risk.

When assessing risk:

- involve stakeholders

- consider engaging experts such as technical specialists, risk experts, researchers, and lawyers

- review risks and lessons learned from similar procurements

Identify

Identify risk events that could impact the procurement negatively or positively.

Ask "What could go wrong? What could go better? What could cause it?"

Risk events may occur within the Agency or external to it.

In the Agency, risks may occur in areas such as:

- the procurement business need, scope, and specifications

- resources allocated and available to the procurement:

- capability and capacity of people, including specialist or professional expertise

- budget

- the procurement schedule/timeframes

- procurement governance, policies, processes, and systems

- internal stakeholders

- systems and process integration

- information security

In the external environment, risks may impact the market, suppliers, and supply chains. For complex procurements, it may be helpful to brainstorm scenarios using methodologies such as SWOT, PESTLE, and PPRACKIF analysis:

- SWOT stands for strengths, weaknesses, opportunities and threats - opportunities and threats are positive and negative risk events by another name

- PESTLE stands for Political, Economic, Sociological, Technological, Legal and Environmental

- PPRACKIF stands for People, Partnerships, Reputation, Agility, Culture, Knowledge, Information and document management, Finances

Analyse

Ask "How likely is it? What would be the impact on value for money?"

The impact may be on one or more value for money factors: fitness for purpose, supplier capability, broader government objectives, total cost of ownership, and timeliness.

Where more than one impact is possible. Select the one that has the highest impact or register different impacts as separate risks.

Evaluate

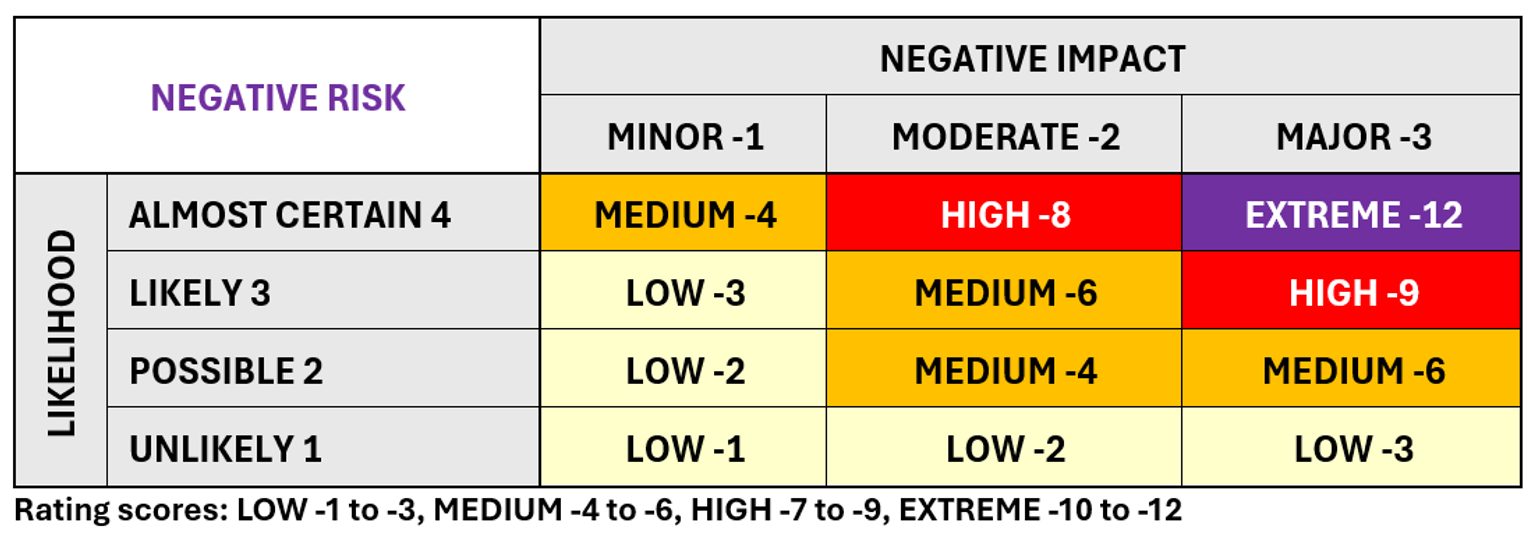

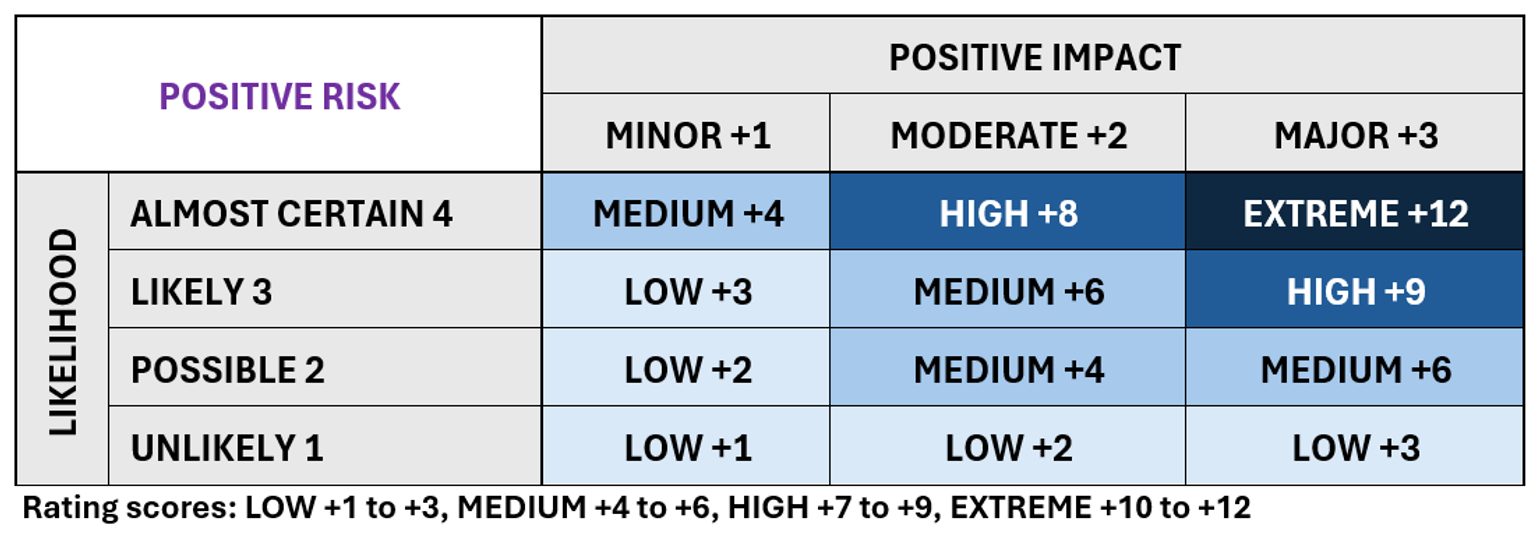

To evaluate risk, determine the likelihood and the impact, and then select the appropriate initial risk rating. The initial risk rating is the level of risk prior to treating the risk. [Mathematically, multiply likelihood and impact to get the rating score].

Use your Agency’s risk evaluation matrix.

Simplified risk evaluation matrix. Alternatively, below is a simplified approach using two evaluation matrices for evaluating negative and positive impacts respectively:

The Manage risk in procurement: Toolkit(opens in a new window) provides these risk evaluation matrices.

Rating descriptions

Descriptions for ratings assist with application and promote consistency. Use descriptions that are meaningful. Consider the examples below.

Treat risk

Treat risk by selecting and implementing measures to change the likelihood and impact of initial risks to an acceptable level of residual risk.

Steps:

- consider the effectiveness of current controls (from whole-of-government and Agency levels)

- develop treatments:

- accept

- avoid

- transfer (including share)

- reduce or increase

- assess residual risk

- implement treatments

Treatments may be applied before a risk event occurs, after the risk event occurs, or both.

Risk treatments should be cost-effective, proportionate, and appropriate for the Agency's risk appetite and resources.

Efficiencies can be gained where a treatment is effective for multiple risks.

Consider performance measures to evaluate the effectiveness of treatments.

Record, monitor, review and report

Record, monitor, review, and report risk functions occur throughout the procurement process. For more detail below.

Scale risk management to complexity and risk

The complexity assessment done at the start of a procurement activity drives the scale of procurement processes, including risk management.

Complexity serves as a proxy for risk until risk is assessed. Once risk events are assessed and the risk profile is confirmed, risk management can be adjusted as necessary.

The same risk management process applies across the range of complexity from simple to strategic procurement. However, the level of detail and effort increases as complexity and risk increase. Indicative scaling of risk management is shown in the accordion below.

Manage risk in supply chains

What is a supply chain?

A supply chain comprises the people, businesses, resources, and activities to produce and provide goods or services to a customer. It is a connected series of inputs and activities.

A supply chain may include labour, raw materials, energy, research and development, design, systems, information, facilities, security, manufacturing, transport, warehousing, sales, delivery, installation, integration, training, maintenance, and repair.

A supply chain may be complex, including:

- multiple suppliers

- many different raw materials as inputs

- components or subsystems manufactured or assembled at multiple facilities

- more than one form of transport may be used for multiple transport legs (such as road - rail - port - road)

- manufacturers or wholesalers may sell direct or through an agent, distributor or retailer

- international elements (political, legal, language and culture, time zones, export/import regulations)

Why manage risk in supply chains?

Manage risk in supply chains to achieve value for money.

Risk in supply chains may have negative impacts. For example, geopolitical factors cause transport of finished goods to take a longer route, delaying delivery of goods and increasing costs.

Risk in supply chains may also have positive impacts. For example, exchange rate uncertainty may benefit an Agency where the exchange rate changes to make imported goods cheaper.

When managing supply chain risk, it may be possible to turn a negative impact to being a positive impact. For example, negative impacts of uncertainties in overseas supply chains may be treated by using local supply chains instead. This may reduce negative impacts and deliver positive economic and social impacts.

How to manage risk in supply chains?

Manage risk in supply chains the same way as any other risk – apply the standard risk management process.

When starting the procurement, category plans may provide detail on supply chain complexity and risk. If not, plan to manage supply chain risk based on the complexity assessment for the procurement.

During market analysis and review, analyse the market’s supply chains and assess the risks. This will inform how to approach the market and what to include in the invitation to supply. Consider including questions for suppliers about risk in their supply chains and how they will manage it.

Once offers have been received from suppliers, and evaluation commences, assess the risk in the supply chains for each offer/supplier. After assessing the risk, treat that risk in negotiations and in the contract as appropriate.

The contract should specify buyer and supplier responsibilities for managing risk. For example, the standard goods and services contract templates have clauses covering responsibilities for subcontracting.

Consider workshopping risk, including supply chain risk, with the preferred supplier prior to contract award. This may enable clear risk allocation and responsibilities for buyer and supplier to be costed and included in the contract.

Once the contract commences, monitor and review risk in the supply chain. Monitor the supplier’s performance of its supply chain risk management responsibilities.

When risk events occur, seek assurances that the supplier is responding effectively. There may be actions that the buyer can take independent of the supplier or to assist the supplier with recovery. Be empathetic, and treat the supplier fairly and respectfully. Collaborate and exercise contractual rights as appropriate. Bear in mind that achieving an effective response is in both parties’ interests.

Tools and support

Access a document version of this guide in the Toolkit and library(opens in a new window).

This guide is supported by:

Buyers can access a course on the Procurement Knowledge Hub:

For more information about how to manage risk in goods and services procurement, please contact the goods and services policy team.

Updated